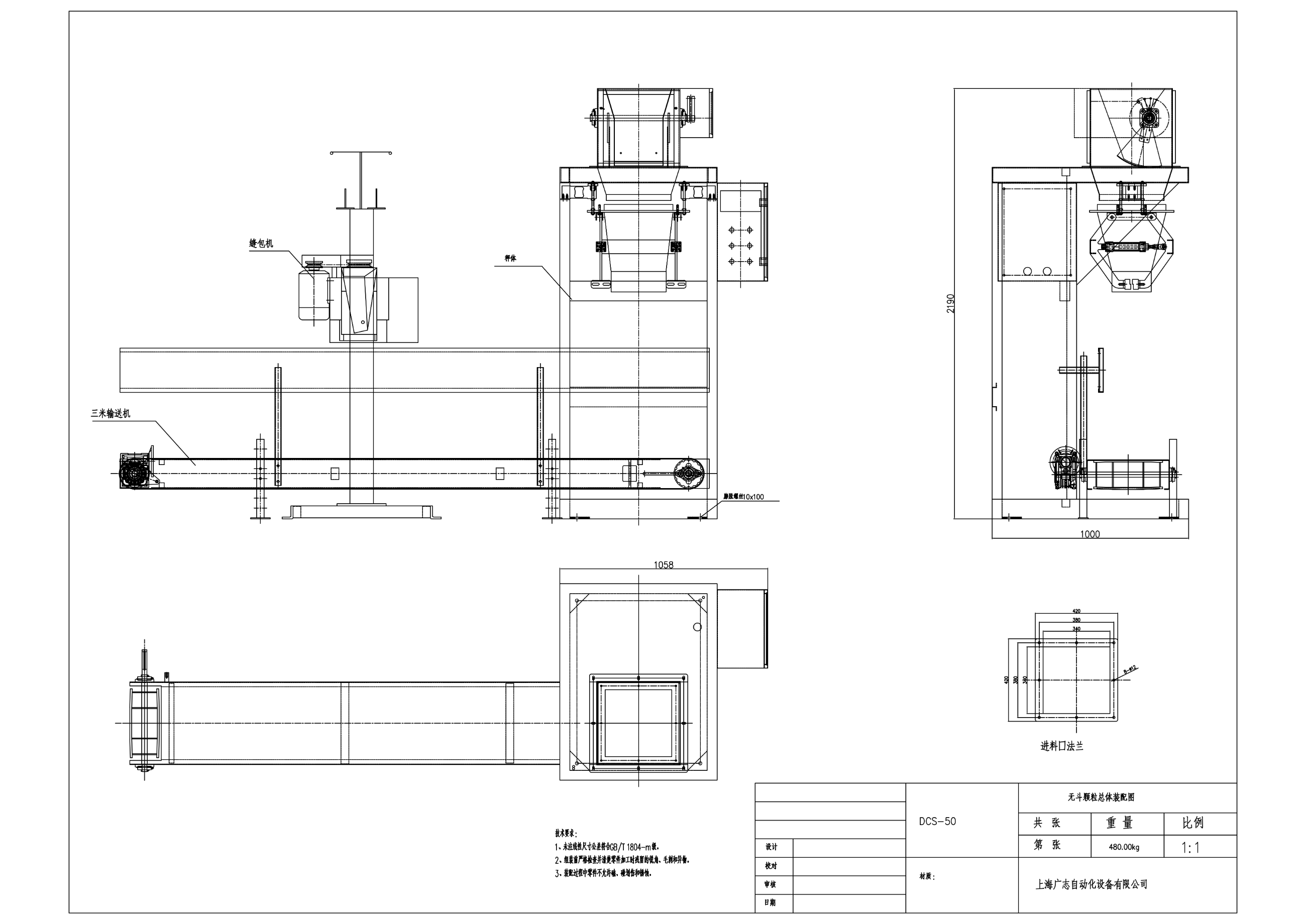

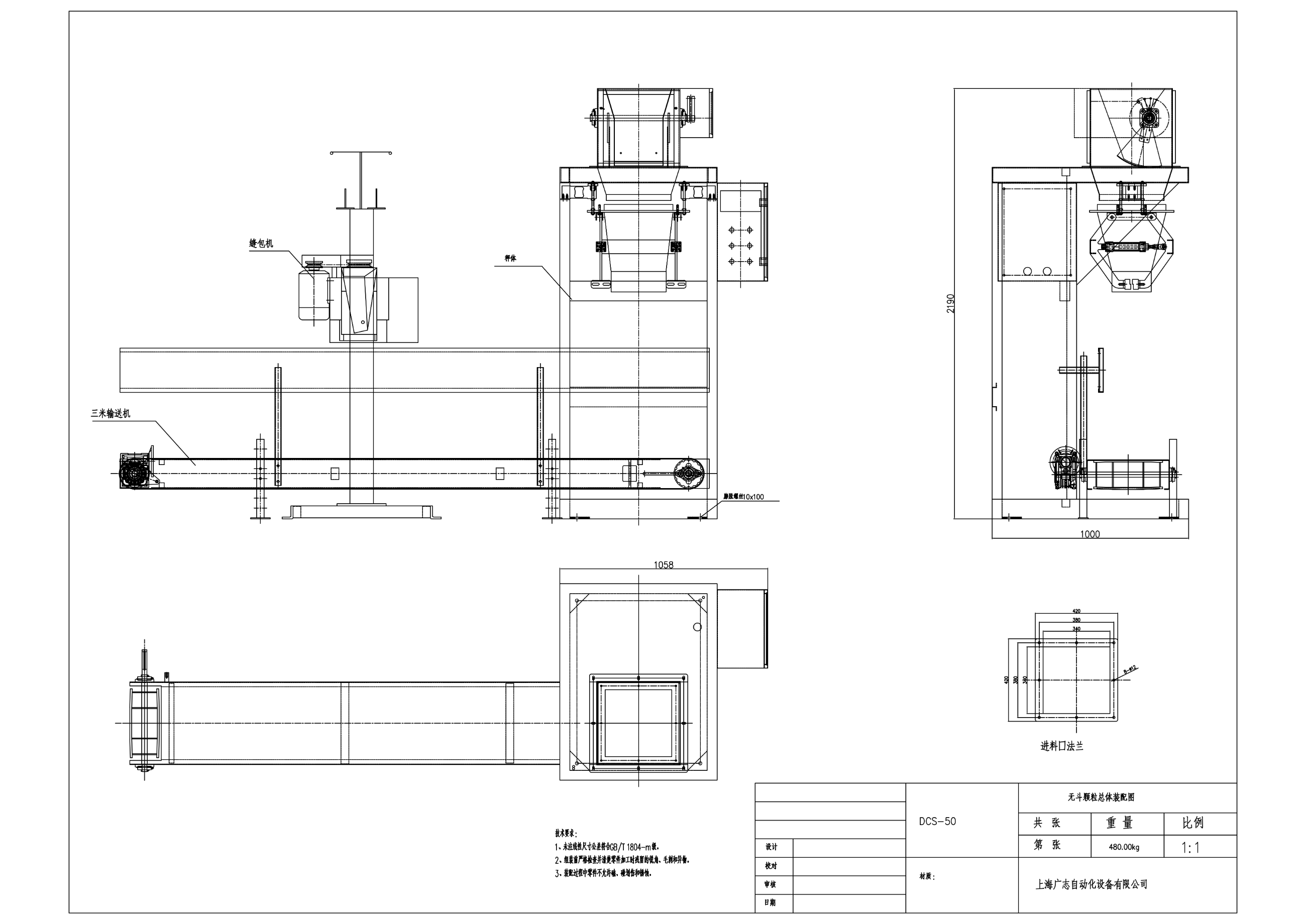

Granule Packaging Machine | Automatic Granule Bagging Machine - Specifications & Features

Our automatic granule packaging machine (also called granule bagging machine) is designed for high-precision packaging of various granular materials, such as grains, seeds, fertilizers, spices, and plastic particles. With advanced PLC control system and touch screen operation, this machine achieves efficient, stable, and labor-saving production, widely used in food, agriculture, chemical, and pharmaceutical industries. Below are the detailed technical parameters and core advantages to help you choose the optimal granule bagging solution.

Technical Parameters of Granule Packaging Machine

Parameter Item | Specification | Remarks |

|---|

Packaging Material | PP/PE film, composite film, kraft paper bag, aluminum foil bag | Suitable for most granular packaging materials |

Granule Type | Free-flowing granules, semi-free flowing granules | Grain, seed, fertilizer, spice, plastic pellet, etc. |

Packaging Weight Range | 10g - 5kg (customizable 5kg - 25kg) | Adjustable according to product demand |

Packaging Speed | 3-6bags/min | Depends on packaging weight and granule type |

Packaging Accuracy | ±0.2% | High-precision weighing sensor ensures accuracy |

Bag Size | (customizable) | Customized for different bag types |

Control System | PLC control + 7-inch touch screen | Easy operation, parameter adjustment, fault alarm |

Power Supply | AC 220V/50Hz or 380V/50Hz, 1.5 - 3KW | According to regional voltage standard |

Air Pressure | 0.4 - 0.6MPa | Stable air supply for sealing and feeding |

Machine Dimension | 3000×1200×2400mm (L×W×H) | Compact design, saving workshop space |

Machine Weight | About 580kg | Sturdy structure, durable in use |

Sealing Type | Heat sealing, cold sealing (optional) | Waterproof, moisture-proof, strong sealing |

Core Advantages of Our Granule Bagging Machine

High Efficiency & Labor Saving: Automatic feeding, weighing, bagging, sealing, and counting, reducing manual operation by 80% compared to manual packaging, greatly improving production efficiency.

Precise Weighing: Equipped with high-sensitivity load cell and intelligent correction system, ensuring packaging accuracy and reducing material waste.

Versatile Application: Suitable for various granular materials and bag types, with adjustable parameters to meet different packaging needs, widely used in multiple industries.

Easy Operation: Humanized touch screen interface, simple parameter setting, no professional training required, convenient for workers to operate.

Stable Performance: Adopting high-quality components and sealed structure, resistant to dust and corrosion, ensuring long-term stable operation with low failure rate.

Customizable Design: According to customer's packaging weight, bag size, and material characteristics, providing customized solutions to match actual production needs.

Application Scenarios

This granule packaging machine is widely used in: Food industry (grains, rice, sugar, salt, spices, snacks); Agriculture industry (seeds, fertilizers, pesticides); Chemical industry (plastic particles, chemical additives); Pharmaceutical industry (granular drugs, health products); Daily necessities industry (detergent granules, cat litter).