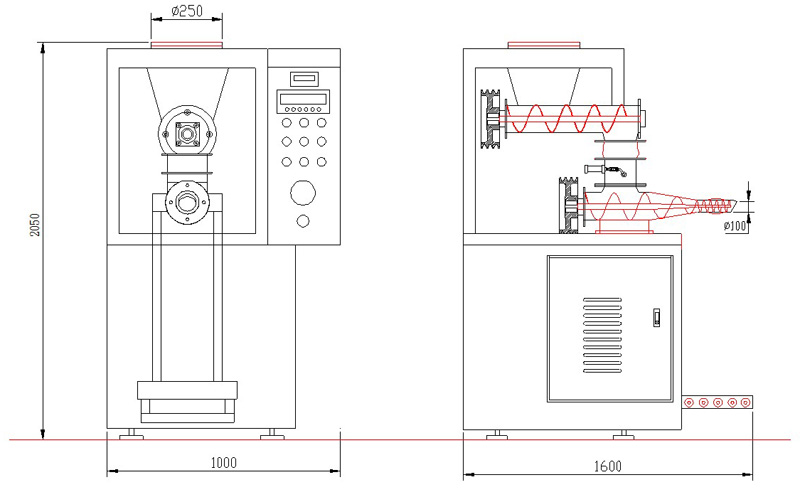

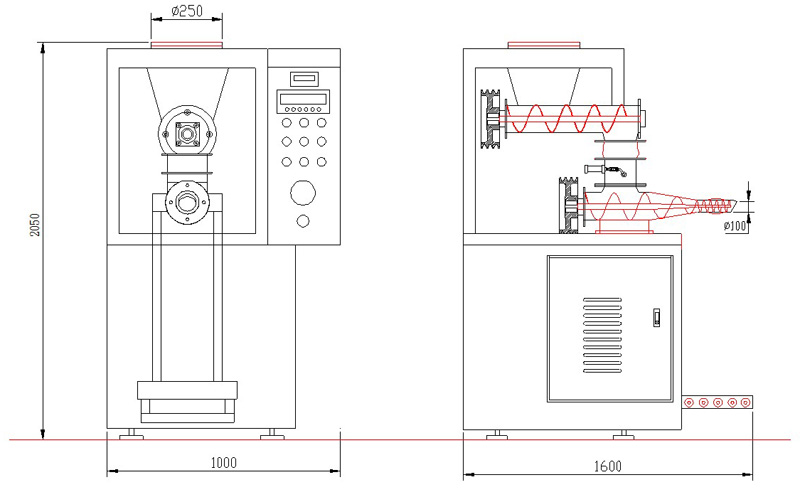

Exhaust-type Twin-Screw Vacuum Quantitative Packaging Machine

Target users of valve-type twin-screw vacuum quantitative packaging machine: Precipitated silica (white carbon black), matting powder, nano-light calcium carbonate, modified ultrafine talc powder, stabilizers, flame retardants, lubricants, various pigments, active modified powders, etc.

Components: Unequal pitch screw, variable diameter screw, exhaust filter device, bag sealing device, weighing system, frequency conversion system, control backup system, etc.

Working principle: The material is compressed and fed through an unequal pitch, conical screw. The difference in speed between the two screws physically squeezes out the gas inside the powder. When the predetermined compression ratio is reached, the pressure valve opens, and the material enters the feeding screw, which directly feeds it into the packaging bag, achieving full packaging density.

Product highlights: Utilizes the principle of physical compression, combined with a filtration device to eliminate gas inside the powder.

Product features: Twin-screw feeding ensures that gas inside the powder is expelled before entering the packaging bag.

System integration: PLC program control, human-machine interface operation, screw relative pressure monitoring, and electronic scale weighing.

GZM-50H Dual Auger Valve Bag Filler - Industrial Powder Packaging Equipment

The GZM-50H Dual Auger Valve Bag Filler is a high-performance industrial packaging machine tailored for precise filling of dry powder materials into valve bags. Adopting advanced dual auger feeding technology, it ensures stable material conveying and uniform filling, making it a reliable solution for businesses in various industries looking to enhance their powder packaging efficiency and consistency.

As a flexible dual auger powder valve bag packer, the GZM-50H is compatible with a wide range of packaging materials and supports diverse production requirements.

Below are its detailed technical specifications:

Specification | Details |

|---|

Model | GZM-50H |

Feeding Method | Dual Auger Feeding |

Applicable Packaging Materials | Woven Fabric / Paper / Paper-Plastic Composite / PVC / EVA |

Packaging Weight Range | 1–50 kg |

Packaging Accuracy | ±0.2–0.5% |

Packaging Speed (25 kg/bag) | 50–80 bags/hour |

Power Supply & Power | 380V 50Hz, 8kW |

Air Supply Requirement | Pressure: ≥0.6MPa; Flow Rate: ≥0.1 m3/min |

Machine Weight | 900 kg |

Overall Dimensions | 1600mm (L) × 1000mm (W) × 2300mm (H) |

Precision and stability are the standout advantages of this dual auger valve bag filler. Boasting excellent weight control accuracy, it guarantees high-quality finished products, effectively reducing material waste and optimizing cost efficiency. The 50–80 bags/hour speed (for 25kg bags) strikes an ideal balance between precision and productivity for medium-volume production scenarios.

Designed for long-term industrial use, the GZM-50H features a rugged structure and stable operation performance. Its compact dimensions save valuable workshop space while ensuring strong load-bearing capacity, making it suitable for limited workshop layouts.

This industrial dual auger feeding packaging machine is widely applied in sectors such as chemicals, building materials, food processing, mineral processing, feed production, and more. It excels in packaging various dry powders—whether free-flowing or poor-flowing—thanks to its dual auger design that prevents material bridging and ensures smooth conveying.

Equipped with user-friendly controls and durable construction, the GZM-50H simplifies daily operation and minimizes maintenance costs. It helps enterprises reduce labor reliance, improve packaging consistency, and meet strict industry quality standards. Choose the GZM-50H dual auger valve bag filler to upgrade your powder packaging line with reliability, precision, and efficiency.