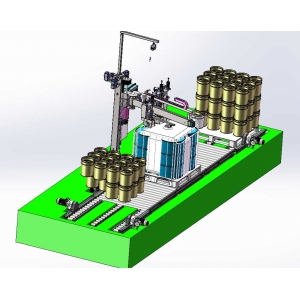

Automatic Drum & IBC Filling Machine: The Ultimate Solution for Bulk Liquid Packaging

In the world of industrial liquid logistics, precision, safety, and speed are non-negotiable. Our Automatic Drum & IBC Filling Machine is engineered to handle the high-volume demands of filling 200L drums and 1000L IBC tanks with surgical accuracy.

Equipped with advanced weighing sensors and an explosion-proof control system, this machine effectively eliminates material waste and ensures a safe working environment for hazardous liquids, chemicals, lubricants, and food-grade materials.

Precision Engineering for Heavy-Duty Performance

Unlike traditional flow-meter systems, our machine uses high-precision load cells to measure material by weight. This "Quantitative Filling" method ensures that changes in temperature or liquid viscosity do not affect your accuracy, providing a consistent $\pm 0.1\%$ filling precision across all batches.

Key Applications

Petrochemicals: Lubricating oil, additives, and fuel components.

Fine Chemicals: Solvents, resins, hardeners, and corrosive acids.

Food Industry: Edible oils, syrups, and bulk liquid ingredients.

Construction: Admixtures, coatings, and liquid sealants.

Technical Specifications

| Feature | 200L Drum Specification | 1000L IBC Specification |

| Weighing Range | $100\text{kg} - 400\text{kg}$ | $500\text{kg} - 1500\text{kg}$ |

| Filling Accuracy | $\pm 0.1\%$ F.S. | $\pm 0.1\%$ F.S. |

| Capacity (Speed) | $40 - 60$ Drums / Hour | $6 - 12$ IBCs / Hour |

| Filling Mode | Top-fill or Submerged (Anti-foam) | Submerged / Deep-tank Fill |

| Nozzle Material | SUS304 / SUS316L / PTFE Coating | SUS304 / SUS316L / PTFE Coating |

| Explosion-Proof | EXiaIIBT4 (Optional) | EXiaIIBT4 (Optional) |

| Power Supply | AC220V/380V; $50\text{Hz}$ | AC220V/380V; $50\text{Hz}$ |

| Air Consumption | $0.5\text{Mpa}$ Clean Air | $0.5\text{Mpa}$ Clean Air |

Core Features & Benefits

1. Advanced Anti-Foam Submersible Technology

For liquids prone to foaming (such as surfactants or certain chemicals), our machine utilizes a submersible filling nozzle. The nozzle dives to the bottom of the drum and lifts gradually as the liquid level rises, preventing turbulence and air bubbles.

2. Intelligent PLC Control System

The integrated PLC (Programmable Logic Controller) allows for:

Multi-Formula Storage: Save up to 30 different filling profiles for quick changeovers.

Dual-Speed Logic: Rapid bulk filling followed by a precise "drip" feed to reach the exact target weight.

Automatic Tare: The system automatically tares the weight of the pallet and the empty container before filling begins.

3. Safety & Environmental Protection

Our machines are built to meet strict GMP and EX-proof standards. The drip-tight nozzle ensures no material is wasted on the container exterior, while the integrated gas collection hood safely vents toxic or volatile vapors away from the operator.

4. Palletized Filling Capability

Maximize your logistics by filling directly on the pallet. Our long-reach swing arm allows the nozzle to reach all four drums on a pallet without moving the pallet itself, significantly reducing forklift operation time.

Operating Workflow

Alignment: The operator aligns the drum/IBC under the filling nozzle (assisted by laser positioning in high-end models).

Start Cycle: A single button press initiates the Automatic Tare and the Submersible Nozzle descent.

Fast/Slow Filling: The machine fills at high speed, switching to slow speed at $95\%$ completion for maximum precision.

Completion: The nozzle retracts, and the drip-collection tray catches any residual liquid.

Data Logging: The exact weight is recorded for inventory and quality control.