Customers using valve-type single-screw quantitative packaging machines:

Full-screw type: Titanium dioxide, wet-process zirconium silicate, mica powder, precipitated barium, particulate powders, and powders with poor flowability and stickiness.

Semi-screw type: Heavy calcium carbonate powder, heavy barium sulfate, quartz powder, putty powder, gypsum powder, magnesium hydroxide, and powders with good flowability and high output.

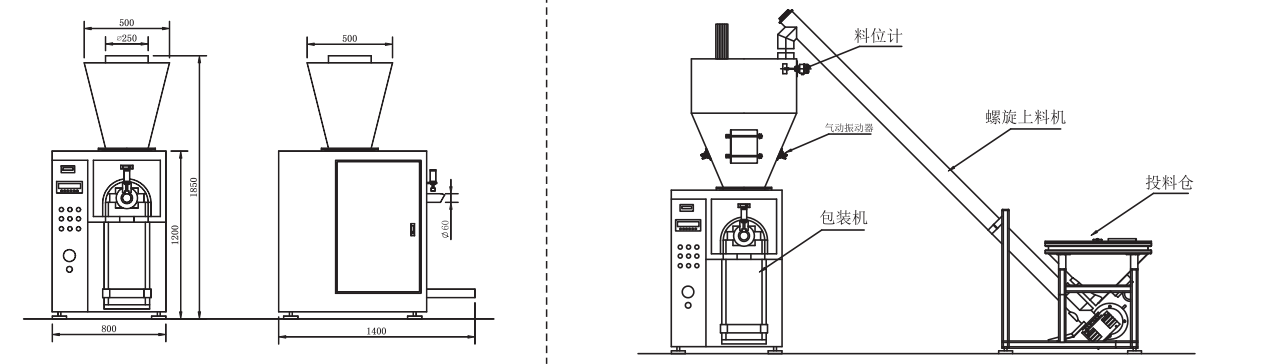

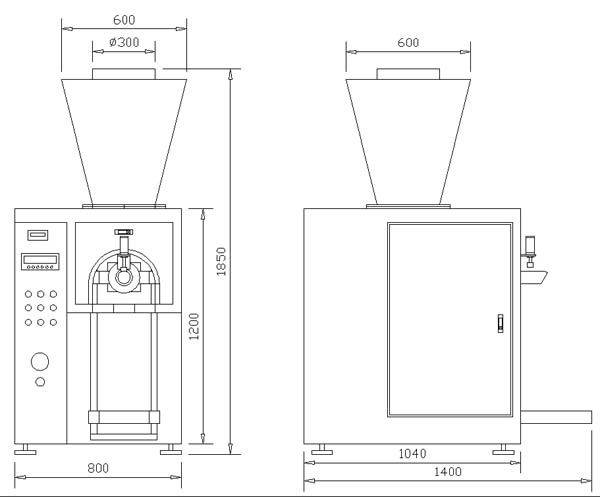

Components: Precision-machined screw, anti-bridging device, rotary valve device, frequency conversion control system, weighing control system, PLC control system, etc.

Working principle: Utilizing a weighing system and PLC control, the frequency conversion screw feeds materials at fast, medium, and slow speeds.

Product highlights: The variable-speed screw is available in full-screw and semi-screw types. The full-screw type directly feeds materials into the packaging bag, primarily designed for materials with high specific gravity, poor flowability, and high viscosity. The semi-screw type uses a high-speed frequency conversion screw and auxiliary air to indirectly feed materials into the packaging bag, primarily designed for materials with good flowability and less clogging (325-2500 mesh).

Product Features: Utilizes variable frequency speed control and electronic automatic metering technology, controlled by a PLC program. It completely solves the problem of ultrafine powder being filled in one pass, featuring accurate metering and dust-free operation.

System Integration: PLC program control, automatic rotary valve, English touch interface, and weighing module.

Feeding Method: Auger feedingApplicable Packaging Materials: Woven fabric / Paper / Paper-plastic composite / PVC / EVA

| Specification | Parameter |

|---|

| Packaging Weight Range | 1–50 kg |

| Packaging Accuracy | ±0.2–0.5% |

| Packaging Speed (25 kg/bag) | 60–180 bags/hour |

| Power Supply & Power | 380V 50Hz, 4kW |

| Air Supply Requirement | Pressure: ≥0.6 MPa; Flow rate: ≥0.1 m3/min |

| Machine Weight | 500 kg |

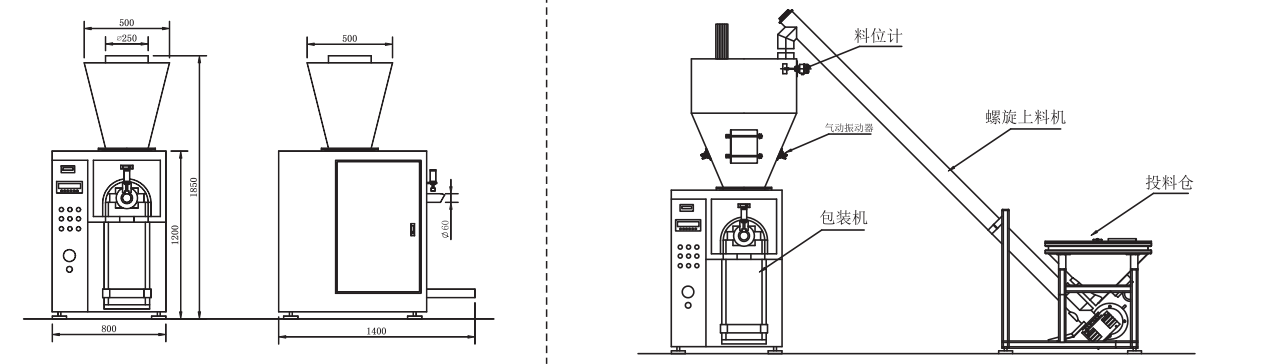

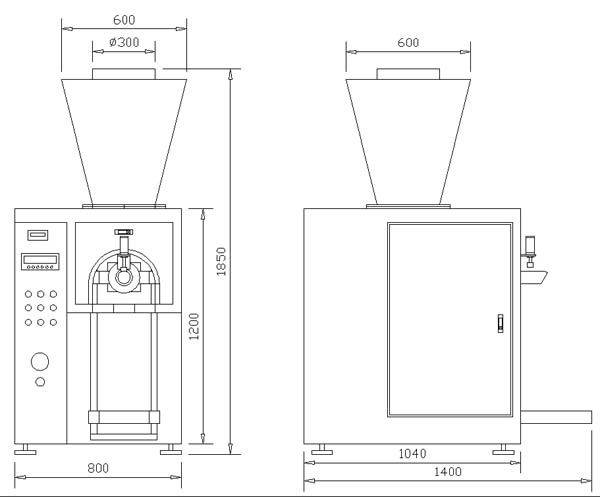

| Overall Dimensions | 800 mm (L) × 1400 mm (W) × 1850 mm (H) |

The GZM-50CH Auger Valve Bag Filler is a professional automatic packaging machine designed for efficient and accurate filling of dry powder materials into valve bags. Engineered with advanced auger feeding technology, this equipment delivers reliable performance for diverse industries, making it an ideal choice for businesses seeking to optimize powder packaging processes.

As a versatile powder valve bag packer, the GZM-50CH is compatible with multiple packaging materials, including woven fabric, paper, paper-plastic composite, PVC, and EVA. It supports a wide packaging weight range from 1kg to 50kg, catering to various production needs—whether for small-batch specialty powders or large-scale industrial bulk packaging.

Precision and efficiency are the core advantages of this auger valve bag filler. With a packaging accuracy of ±0.2–0.5%, it ensures consistent weight control for high-quality end products, reducing material waste and improving cost-effectiveness. For 25kg bags, the machine achieves a packaging speed of 60–180 bags per hour, balancing productivity with precision to meet medium to large production demands.

Built for industrial durability, the GZM-50CH features a robust structure with stable operation. It operates on a 380V 50Hz power supply with a 4kW power rating, and requires a compressed air supply of ≥0.6MPa pressure and ≥0.1 m3/min flow rate. Weighing 500kg with compact overall dimensions (800mm L × 1400mm W × 1850mm H), it saves workshop space while maintaining strong load-bearing capacity.

This automatic auger feeding packaging machine is widely applied in industries such as chemicals, building materials, food processing, minerals, feed, and more. It excels in packaging powders like cement, flour, chemical additives, mineral powder, feed additives, and other dry materials—whether free-flowing or poor-flowing.

Equipped with user-friendly controls and a durable design, the JKF-159CH simplifies operation and minimizes maintenance costs. It helps businesses reduce labor dependency, improve packaging consistency, and comply with industry quality standards. Invest in the GZM-50CH auger valve bag filler to elevate your powder packaging efficiency and reliability.