ChemMaster CM-9000 Series

Intelligent Automated Filling Line for Specialty Chemicals

±0.05% Accuracy ? 60 Drums/H ? ATEX/ISO 15848 Dual-Certified ? Military-Grade Sealing ? Blockchain Traceability

Core Specifications

| Parameter | CM-9100 (Standard) | CM-9200X (Explosion-Proof) | CM-9300C (Corrosion-Resistant) |

|---|

| Capacity Range | 20-200L (±0.05%) | 20-200L (±0.08%) | 20-200L (±0.06%) |

| Throughput | 60 Drums/Hour | 55 Drums/Hour | 50 Drums/Hour |

| Viscosity Range | 1-500,000 cP | 5-300,000 cP | 50-1,000,000 cP |

| Leak Rate | <10?? mbar·L/s (Helium Test) | <10?? mbar·L/s | <10?1? mbar·L/s |

| Material Contact | 316L EP (Ra<0.4μm) | Hastelloy C276 | Zirconium Alloy Lined (Zr702) |

| Sealing System | Dual-Lip Mechanical Seal + Laser Welding | Metal Bellows Seal + Mag Drive | Triple Hard Seals |

| Certifications | - | ATEX Zone 1/ISO 15848 Class A | NACE MR0175 |

| Cleaning Cycle | CIP 15-min | Solvent Purge + N? Flush | Electropolishing |

| Changeover Time | <90s (Tool-Free) | <100s | <85s |

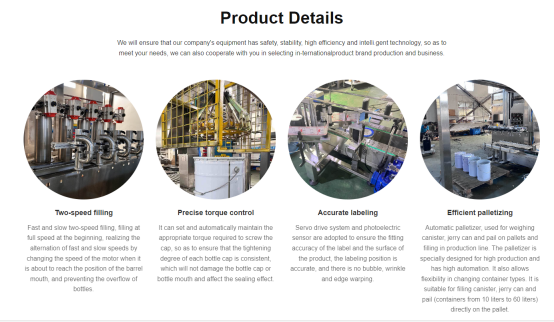

5 Core Technologies

1. ZeroLeak? Fortress Sealing

Military-Grade Performance:

| Chemical | Industry Leak Rate | CM-9000 Leak Rate |

|---|

| Hydrofluoric Acid (48%) | 10?? mbar·L/s | <10?1? mbar·L/s |

| Chlorosilanes | 10?? mbar·L/s | <10?? mbar·L/s |

| Epichlorohydrin | 10?? mbar·L/s | <10?? mbar·L/s |

2. TitanShield? Corrosion Defense

| Component | CM-9300C Material | Corrosion Resistance |

|---|

| Flow Path | Zirconium Alloy (Zr702) | Withstands Boiling Aqua Regia (0.01mm/yr) |

| Sensors | Sapphire Probes + PTFE Coating | Resists 48% HF Acid |

| Seals | Reinforced Graphite + PTFE Composite | Tolerates Fuming H?SO? (40°C) |

Industry-Specific Solutions

Electronic Chemicals

Critical Control:

Agrochemicals

| Challenge | Innovation | Result |

|---|

| Suspension Settling | 80°C Path + Ultrasonic Agitation | >99.5% Uniformity |

| Crystallization | Dynamic Temp Control (±0.5°C) | Zero Clogging |

| Static Accumulation | Ionized Air Curtain (10? ions/cm3) | Surface Charge <10V |

Pharma Intermediates

Smart Control System

ChemBrain? Industrial AI

AI Capabilities:

Risk Mitigation:

| Risk Factor | Response Time | Action |

|---|

| Temp Deviation >2°C | 0.5s | Emergency Cooling |

| Pressure Fluctuation >10% | 0.3s | Dual-Valve Isolation |

Quality Guardian:

| Parameter | Precision |

|---|

| Moisture Content | ±0.5ppm |

| Metal Ions | 0.1ppb |

Certifications

? ATEX 2014/34/EU Zone 1 (CM-9200X)

? ISO 15848-1 Class A Seal Certification

? ASME BPE-2022

? NACE MR0175 (CM-9300C)

? SIL-3 Functional Safety

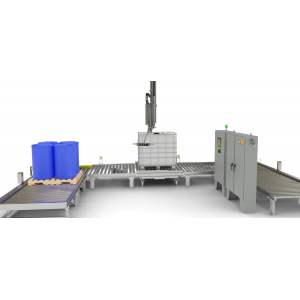

APPLICABLE BARREL TYPE

COMPANY PROFILE

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

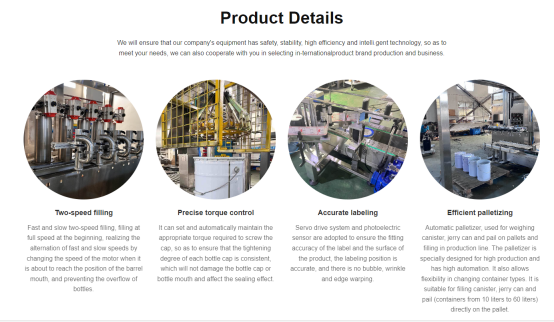

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance