GantryMaster GM-10000 Series

Robotic Gantry-Style Drum & Tote Filling System

±0.05% Accuracy ? 60 Containers/H ? 20-1,000L Capacity ? Industry 4.0 AI Integration

Technical Specifications

| Parameter | GM-1010 (Standard) | GM-1020X (ATEX) | GM-1030P (Pharma) |

|---|

| Container Range | Drums (200L) ? IBC Totes (1000L) ? Pails (20L) | Same + Safety Cans | Same + USP Containers |

| Throughput | 60 Containers/Hour | 55 Containers/Hour | 50 Containers/Hour |

| Accuracy | ±0.05% Gravimetric | ±0.08% | ±0.06% |

| Filling Volume | 20-1000L (±0.05%) | 20-1000L (±0.08%) | 20-1000L (±0.06%) |

| Gantry System | 3-Axis Linear Robots<br>? ±0.1mm Positioning<br>? 150kg Payload<br>? 10m/s Speed | Same + ATEX Motors | Same + Cleanroom Rails |

| Filling Technology | Coriolis Mass Flow<br>? Auto-Height Nozzle<br>? Submerged Filling | ATEX Gear Pump | Peristaltic Pump (FDA) |

| Material Contact | 316L EP (Ra<0.4μm) | Hastelloy C276 | Glass-Lined Path |

| Drip Control | Vacuum Suction + Capillary Break (<0.03ml) | Same | Teflon Scraper (<0.01ml) |

| Changeover Time | <90s (Tool-Free) | <100s | <85s |

| Safety System | Laser Scanners + Light Curtains | ATEX Pressurized Zone | SIL-3 Emergency Stop |

| Power | 480V/60Hz, 22kW | 24VDC Ex ia | 480V/60Hz, 18kW |

| Certifications | CE, ISO 13849-1 | ATEX Zone 1 | FDA 21 CFR 210/211 |

Core Innovations

1. OverheadRail? Robotic Mobility

Performance Metrics:

| Container | Positioning Time | Fill Speed | Accuracy |

|---|

| 200L Drum | 1.8s | 25L/sec | ±0.04% |

| 1000L IBC | 2.5s | 40L/sec | ±0.06% |

| 20L Pail | 0.9s | 8L/sec | ±0.03% |

2. Lift&Lock? Nozzle System

| Technology | Function | Performance |

|---|

| Auto-Height Probe | Ultrasonic Level Detection | ±1mm Depth Control |

| Rotating Seal | 360° Teflon Wiper | <0.02ml Residual |

| Ionized Air Curtain | Static Dissipation (10? ions/cm3) | <5kV Surface Charge |

Industry-Specific Engineering

Chemicals & Solvents

| Feature | ATEX Solution |

|---|

| Vapor Containment | Nitrogen Blanketing (O?<0.3%) |

| Spill Defense | Drip Tray + Vacuum Recovery |

| Corrosion Resistance | Zirconium Nozzle Tips |

Food & Pharma

Aseptic Design:

CIP/SIP Capability:

| Parameter | Performance |

|---|

| Clean Time | 15-min Cycle |

| Sterility Assurance | SAL 10?? |

Industrial Lubricants

| Component | Heavy-Duty Solution |

|---|

| 1000L IBC Handling | Dual-Robot Synchronized Lift |

| High-Viscosity | 80°C Path Heating |

| Settling Prevention | In-line Dynamic Agitator |

Smart Control Ecosystem

**15" AI HMI with GantryOS?**

AI-Driven Features:

Adaptive Filling:

| Condition | Action |

|---|

| Foam Detection | Flow Rate Reduction |

| Container Tilt >2° | Nozzle Angle Adjustment |

Preventive Maintenance:

| Component | Alert Threshold |

|---|

| Rail Wear | Vibration >4mm/s |

| Seal Degradation | Friction >12N |

Technical Advantages

Robotic Precision Engineering:

? Overhead Mobility System:

| **Spec**| **Performance**|

|-----------------------|------------------------|

| Positioning Accuracy | ±0.1mm |

| Max Speed| 10m/s|

| Payload Capacity | 150kg|

? Zero-Spill Architecture:

1. Submerged Nozzle (200mm Depth)

2. Vacuum Suction (-0.8bar)

3. Coanda Adhesion Design

? Multi-Container Intelligence:

- Auto-Container Recognition (Vision System)

- 90s Format Changeover

- Collision-Free Multi-Robot Coordination

Certifications

? ATEX 2014/34/EU Zone 1 (GM-1020X)

? FDA 21 CFR 210/211

? CE EN ISO 13849-1 PLd

? ISO 9001:2015

? UL 508A

Performance Validation

Dow Chemical Case Study:

*"After 6 months using GM-1010:

Output: 22 → 60 Drums/Hour (+173%)

Spill Incidents: 18/month → 0

Material Savings: $380,000/year

ROI: 5.1 months"*

Why Choose GM-10000?

Transformative Flexibility:

? Universal Container Handling:

- Drums, Totes, Pails, Jerrycans

- 20L to 1000L Capacity

- Auto-Height/Lid Detection

? Military-Grade Safety:

| **Feature**| **Certification** |

|----------------------|--------------------------|

| Laser Safety Scanners | SIL-2 PLd |

| ATEX Pressurization | Zone 1 Compliance|

| Emergency Stop| ISO 13850 |

? Industry 4.0 Integration:

- Digital Twin Simulation

- OPC UA Connectivity

- Predictive Analytics Dashboard

APPLICABLE BARREL TYPE

COMPANY PROFILE

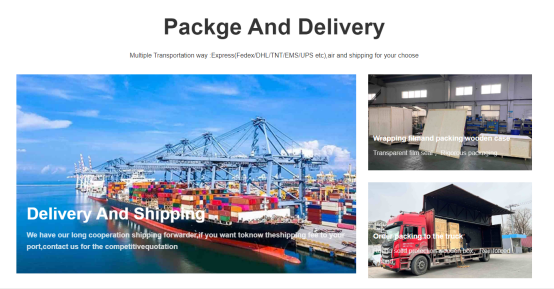

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

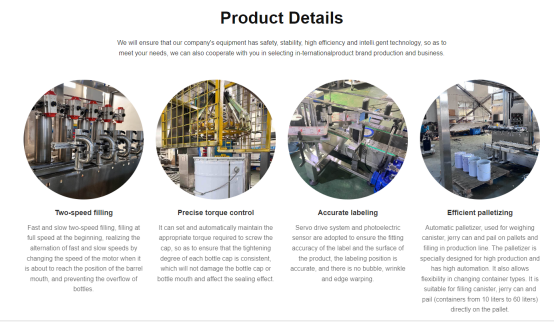

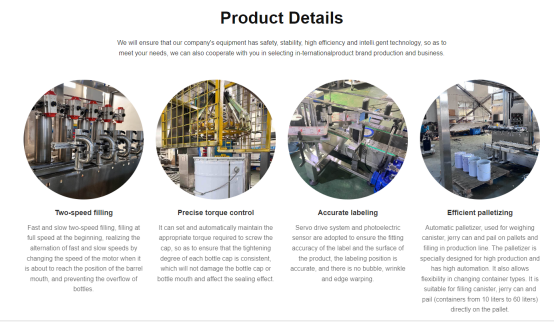

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance

v